To All of Our Friends, Our Enemies, Our Families, Our Readers and All of Humanity:

May we all have a year filled with wonder, success, prosperity and awe. May all our wishes and dreams come true. May we all discover freedom and brotherhood. May the Fates smile upon all of our endeavours.

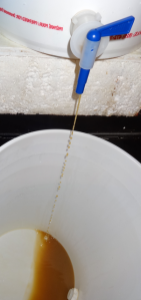

Please join us in welcoming the New Year by singing along with us with a good old Scottish favourite from Rabbie Burns (take your pick according to your inclination) while we share a wee nip of Scotch together:

Here are the Words:

Should auld acquaintance be forgot,

and never brought to mind?

Should auld acquaintance be forgot,

and auld lang syne?

CHORUS:

For auld lang syne, my jo,

for auld lang syne,

we’ll tak’ a cup o’ kindness yet,

for auld lang syne.

And surely ye’ll be your pint-stoup!

and surely I’ll be mine!

And we’ll tak’ a cup o’ kindness yet,

for auld lang syne.

CHORUS

We twa hae run about the braes,

and pou’d the gowans fine;

But we’ve wander’d mony a weary fit,

sin’ auld lang syne.

CHORUS

We twa hae paidl’d in the burn,

frae morning sun till dine;

But seas between us braid hae roar’d

sin’ auld lang syne.

CHORUS

And there’s a hand, my trusty fiere!

and gie’s a hand o’ thine!

And we’ll tak’ a right gude-willie waught,

for auld lang syne.

CHORUS

The Traditional Burns Auld Lang Syne:

Gregorian Auld Lang Syne:

And if you prefer Trance Auld Lang Syne:

Happy New Year from The Munchkin and The Gnome!!